New material for better hip implants

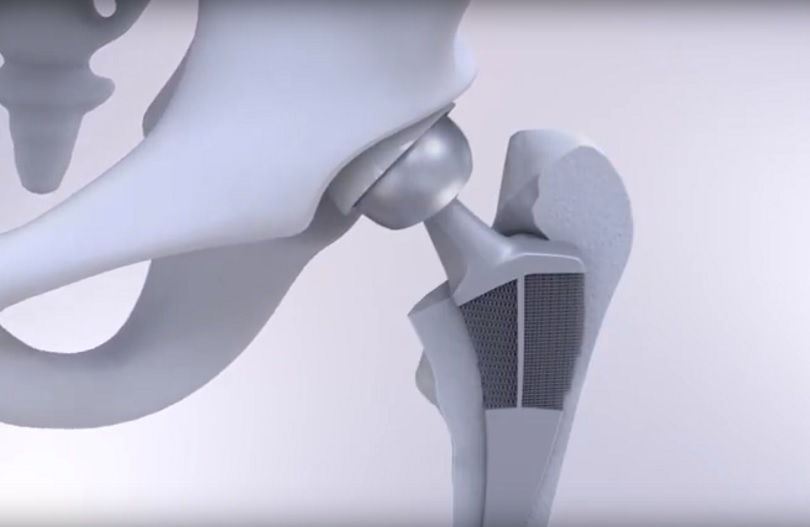

Researchers at Delft University of Technology (TU Delft) have developed a new hybrid material that could possibly be used to produce better hip implants. This material ensures more secure anchoring of the implant and stimulates bone growth. The researchers published their results yesterday in the scientific journal, Materials Horizons.

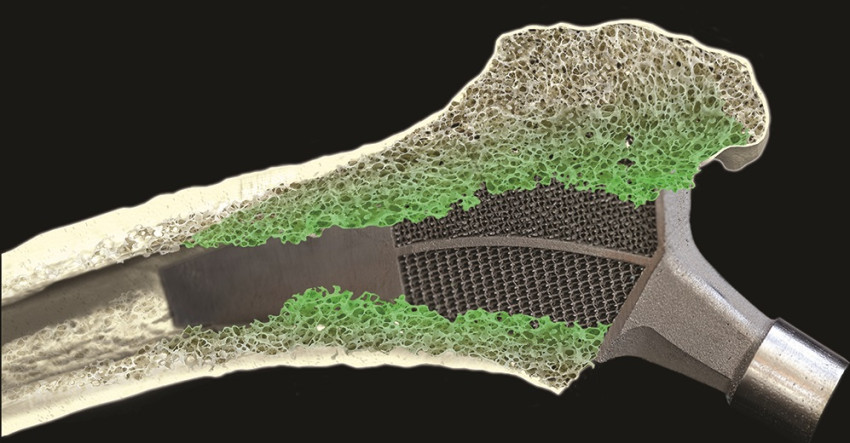

‘We wanted to develop a material that becomes thicker on elongation,’ says researcher, Eline Kolken. ‘I often explain the situation using the example of a fist: When a fist is bent inwards, the skin on the outside stretches.’ The same things happen in a hip implant when the wearer moves and thus exerts pressure on the implant. The outside of the implant becomes longer and thinner, so that the implant loses contact with the bone. Bone is actively broken down and built up, depending on the pressure exerted. If the implant no longer presses against the bone, the bone slowly breaks down. The implant then becomes loose, which is the most frequent reason for implant replacement.

PERMANENT CONTACT

Kolken and her group therefore developed a special material that becomes thicker when it is elongated. It consists of a network of layered mesh-like structures. ‘Materials that become thicker on elongation are practically unknown in nature. They are to be found, for example, only in tendons and cat skin,’ says Kolken. By using this new material for the outer surface of an implant, contact with the bone remains intact during movement of the joint. ‘The bone does not break off, so that the implant remains firmly seated.’

HYBRIDS

The new material is made from 3D-printed titanium. ‘The material itself does not provide this special property, as that comes from the form in which it is printed.’ The new material is used in the implant together with a different type of material with a honeycomb structure, which is why the researchers call the whole combination a hybrid material.

It will still take some time before the new material undergoes clinical tests. In the coming years, the Delft-based group plans to work together with researchers from various university hospitals to determine how the hybrid material can be used to improve present-day implants.

If you found this article interesting, subscribe for free to our weekly newsletter!

Meer artikelen

Een AI-fabriek in Groningen

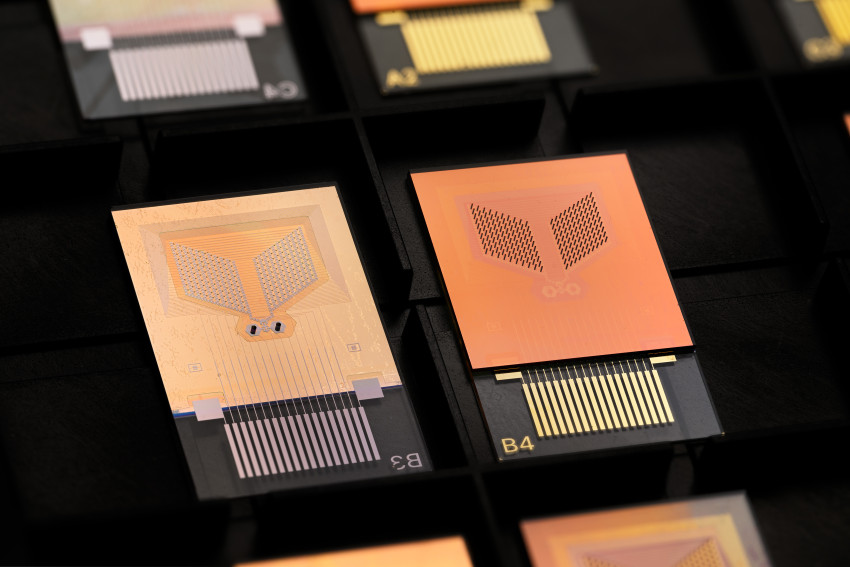

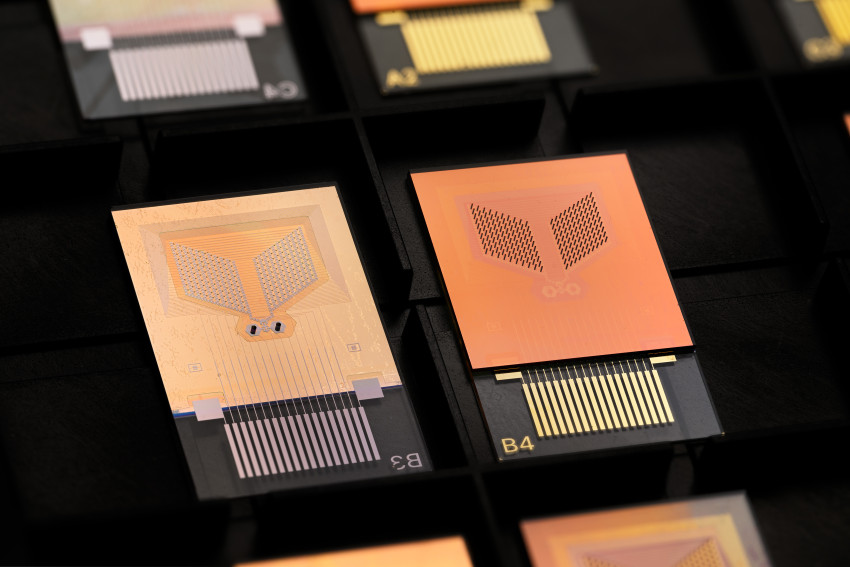

Gezondheid meten via zweetdruppels

Nieuwste artikelen

Een AI-fabriek in Groningen