Recycling batteries could be much more efficient

A new approach to recycling lithium batteries uses half as much energy as other methods. And that would make battery recycling much more popular. And that is really necessary, as lithium-ion batteries are used in a huge number of devices and cars.

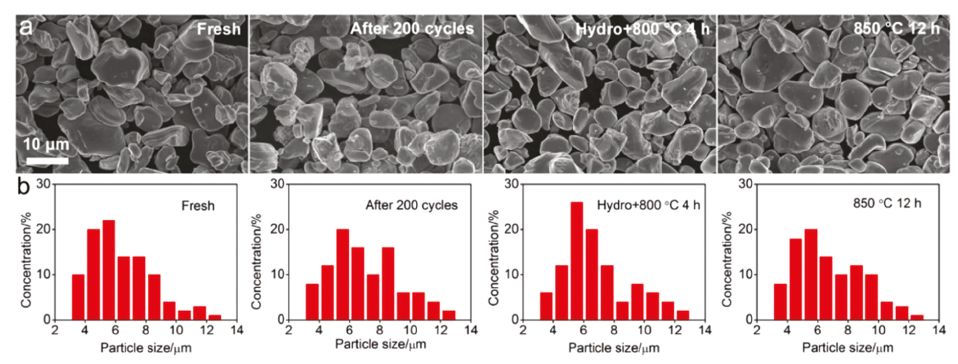

Researchers at UC San Diego in the US managed to recycle the lithium portion of lithium-ion batteries without crushing it first. That allows the microscopic structure of the lithium particles to be retained, and a battery using recycled lithium is much more usable.

Drying and heating

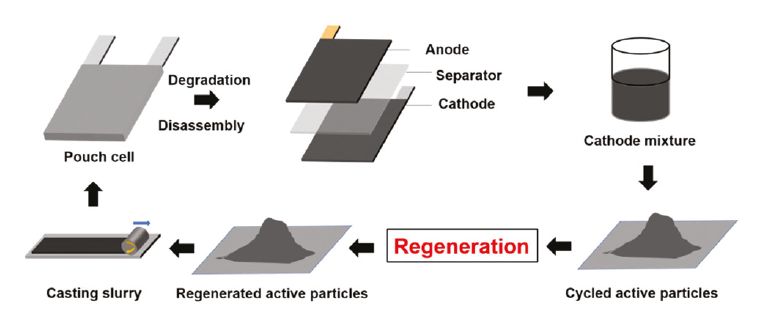

The researchers first disassembled the battery proper, then they removed the cathode (the lithium portion) and dissolved it in a bath of hot lithium salt. They then dried the mix, which was heated to 800 °C. After cooling, the lithium was once again ready for use.

In a lab experiment, a battery produced using the new material performed almost as well as a 'fresh' battery. In terms of charging time, lifespan and capacity, the recycled battery was equally as good.

Environment

At the moment, just five percent of lithium batteries worldwide are recycled. And that's a problem, given that a huge number of devices, such as telephones, laptops and electric cars, are full of such batteries. Storing them or disposing of them are both bad for the environment. What's more, there is an imminent shortage in the supply of lithium, making it increasingly expensive.

Microstructure

The fact that the batteries are not often recycled is due to the energy costs. The battery first has to be ground down, before the material is melted or dissolved in acid. Production of that acid or heating of the battery costs a great deal of energy, and it destroys the micro-structure of the lithium particles. But it's precisely this structure that makes these batteries so good.

The new method of recycling batteries seems much simpler, more efficient and better. But the technology is not yet ready for mass application. One major bottleneck is separating the lithium from the rest of the battery. This was done by hand in this study, but that is of course not an option on a large scale.

If you found this article interesting, subscribe for free to our weekly newsletter!

Meer artikelen

Een AI-fabriek in Groningen

Gezondheid meten via zweetdruppels

Nieuwste artikelen

Een AI-fabriek in Groningen