Construction of wood gasification plant has begun

The construction of the Netherlands’ first wood gasification plant has begun in Amsterdam. The plant will use pruning waste from woodland and parks as well as waste wood from the building trade, as raw material to generate electricity and heat.

The plant, set to start generating green energy next year, is being constructed by Bio Energy Netherlands, founded just last year. Initially the plant will feature two gasification reactors with a total production capacity of 10 MW. A third will be added later to boost capacity to 15 MW.

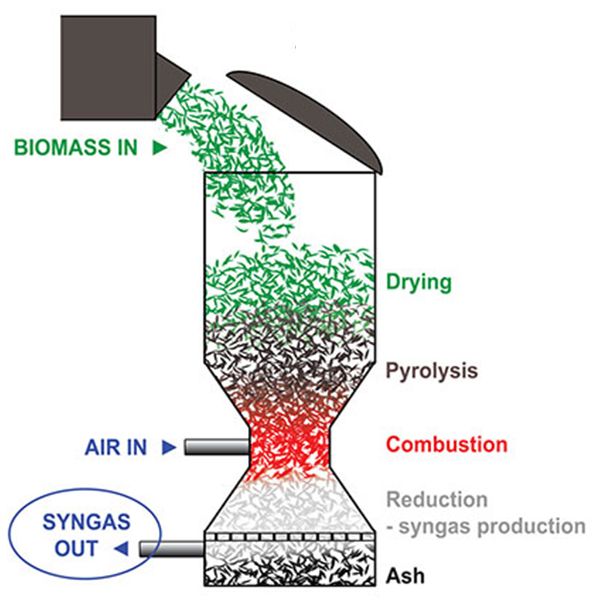

The gasification technique used is the so-called Fixed Bed Down Draft Gasifier. Wood chips enter the reactor at the top, pass through a vacuum lock and are then 'combusted’ – or rather converted into a different substance – in an oxygen-starved environment. This creates a syngas that is sent to a motor that in turn uses it to generate electricity.

‘The technology was developed by US company Zero Point Clean Tech’, explained Raoul Witteveen, one of the financiers of Bio Energy Netherlands. The major benefit of this gasification technique is that almost no tar is formed in the gas using this method. ‘That does happen with other gasification techniques. And it requires a great deal of effort to then remove the tar.’

Bio Energy supplies power to the network in the form of green electricity, and the heat released by the gasification process and from the gas-powered motor goes to a nearby Afval Energie Bedrijf (AEB, waste energy company), run by Amsterdam City and serving Amsterdam’s heating mains.

Preprocessing

The wood is pruning waste from woodland and parks and waste wood from the building trade. ‘These are residues with no other practical use. However, the wood must first be processed: we dry it and chip it.’

The residual product of the wood chips is active coal, a charcoal-like product that can be used as a soil improver, so-called biochar. Witteveen: ‘The carbon in the pruning waste is returned to the soil, without the greenhouse gases that are released by rotting wood.’

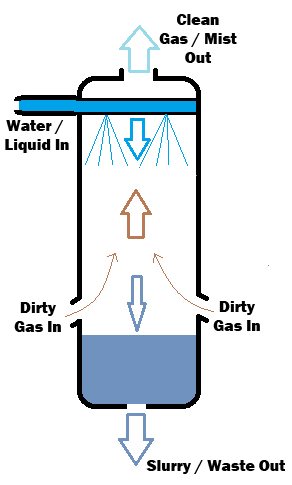

The syngas that is created by the oxygen-starved conversion of the wood does have to be cleaned. This is done using a water scrubber, in which a water mist catches all solid particulates in the gas, and collects them in a so-called baghouse filter. ‘We thus remove residues of metals originating from paint remnants on the wood, and other particulate matter.’

The cleaned gas then goes to a Jenbacher gas motor that drives a generator. ‘That motor works on low-energetic gas. Our gas has an energy content of some 6 GJ/m3. By contrast, natural gas contains six times more energy.’

By supplying electricity, heat and active coal, Witteveen aims to sell all the products the plant produces. ‘This is the only way in which we can make this business case feasible, including a modest subsidy from the SDE+ sustainable energy fund.’

Hydrogen

Witteveen wants to further expand this approach in future. ‘In the third production, we will also desulphurise, and together with energy research centre ECN we are currently looking at how to also remove the hydrogen and carbon dioxide from the syngas. The hydrogen can then be supplied to the industry or filling stations, and the CO2 can be processed further, for instance through storage or some beneficial use.’

Gasification is one of the ways of generating power from biomass. This is currently only done by adding wood chips to coal-fired power plants, or by burning the wood chips alone, as at the Eneco Bio Golden Raand power plant. As opposed to simple combustion of the wood, gasification not only generates heat, but also results in a wide range of products like hydrogen, carbon dioxide and methane.

SCW systems in Alkmaar currently has a plant under construction that is designed to supercritically gasify biomass.

Bio Energy Netherlands was founded last year by Witteveen and Robert-Jan van Ogtrop, both wealthy individuals due to the sale of previous business operations. They are focusing on promoting sustainable energy projects. Ogtrop is also founder of the Circle Economy consultancy.

If you found this article interesting, then subscribe for free to our weekly newsletter.

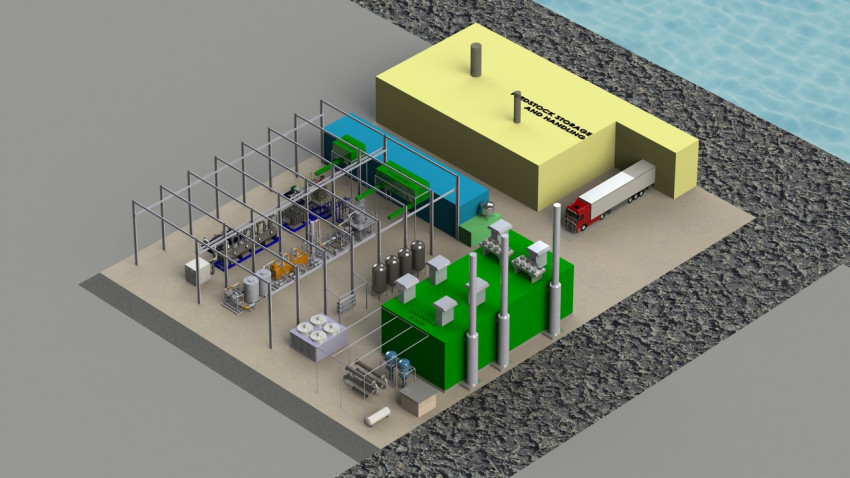

Opening image: impression of the biomass gasification plant of Bio Energy Netherlands in Amsterdam’s docklands.