Contact lens measures glucose in tears

Engineers and materials scientists in South Korea have developed a contact lens that monitors glucose levels in tear fluid. This application has been under development for some time, but the material they are using represents a major step forward.

It appears in many futuristic news articles about the future of care: the contact lens as the perfect measuring device (in addition to the plaster and the tattoo). But it also has other benefits. A contact lens can be worn by most people without problem. It is in contact with a bodily fluid – tears. And it also acts as a mini platform onto which the electronics can be integrated.

The thing is, no one has yet managed to construct a decent measuring contact lens. The South Korean scientists and engineers have now taken a huge leap forward. In the journal Science Advances (open access), they describe how they integrate the necessary components into a soft contact lens.

The thing is, no one has yet managed to construct a decent measuring contact lens. The South Korean scientists and engineers have now taken a huge leap forward. In the journal Science Advances (open access), they describe how they integrate the necessary components into a soft contact lens.

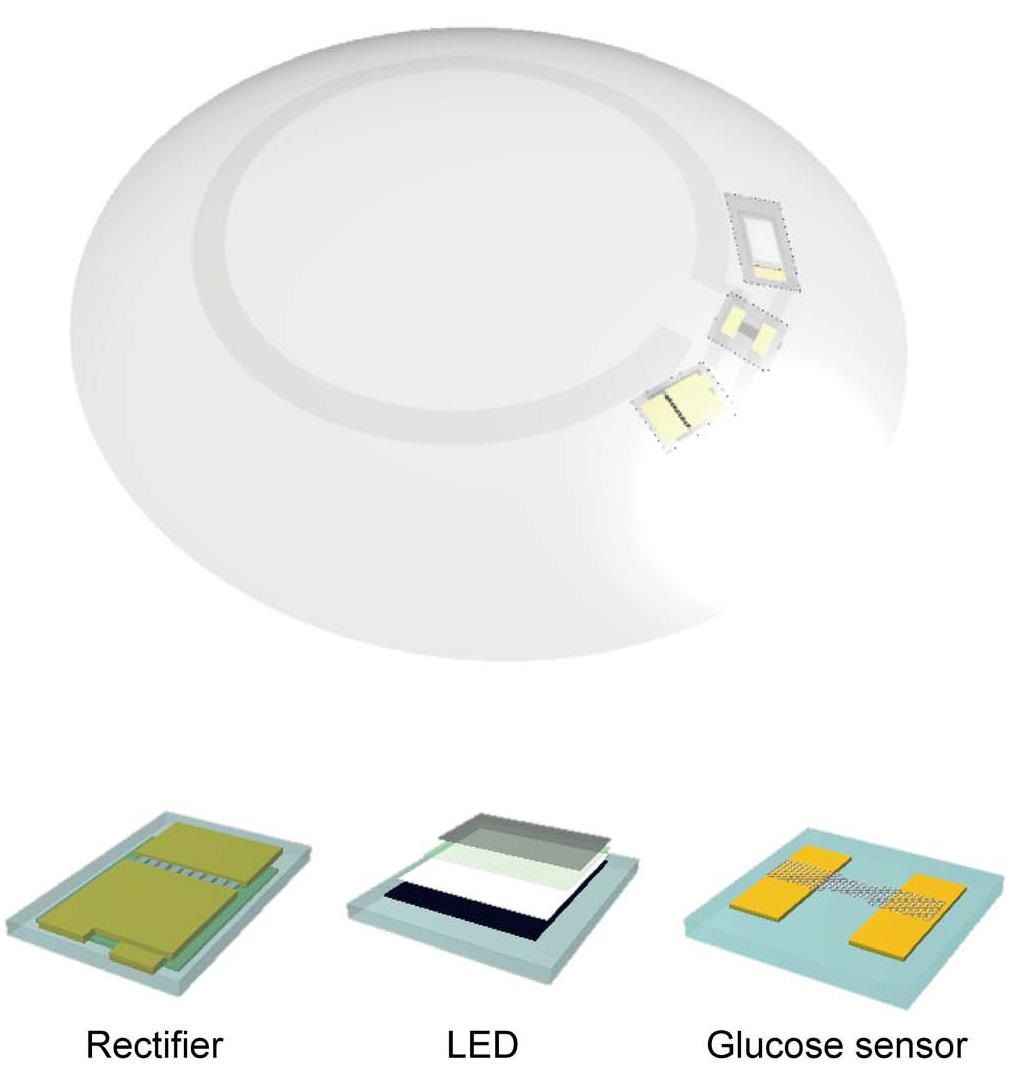

On a soft and transparent material, they place a glucose sensor, a rectifier, an antenna and a mini display of just a single pixel (see illustration).

The lens that monitors

The idea is that, within a couple of years, diabetes patients can wear this lens as it continually monitors the blood-sugar levels in the tear fluid (tear fluid reacts with a delay to glucose levels in the blood). If the level rises or falls too much, then the user is alerted directly, by a small screen in the lens, for instance. Furthermore, such a ‘smart contact lens’ generates a great deal of long-term data, with which the illness can hopefully be managed even better.

Damaging the eye

The reason it has been so difficult until now is down to the small electronic components that need to be mounted on or in such a lens. After all, conventional electronics are made up of rigid, sometimes even sharp parts that could damage the eye. The researchers have solved this problem by making all components from a flexible and stretchable material, of which more later. What's more, electronics in a contact lens could partially disrupt the vision of the user, which is not really very handy. The South Korean engineers have resolved this issue by placing the mini electronic components at the edge of the lens, outside the pupil.

Flexible and soft

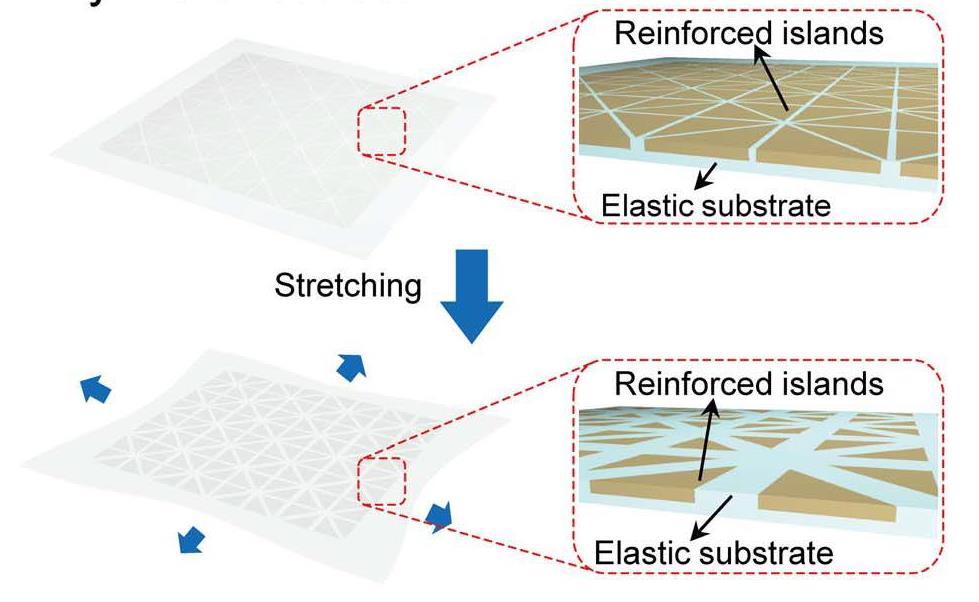

The real genius of this approach is found in the design of the contact lens, and the interplay between form and material choices. The contact lens is made up of two types of material: a very elastic silicone substrate that deforms easily, yet containing little islands of a more rigid polymer. The trick is that these little islands are used for mounting the electronic components, or parts thereof. In this way, the lens can be distorted without damaging the electronics.

The real genius of this approach is found in the design of the contact lens, and the interplay between form and material choices. The contact lens is made up of two types of material: a very elastic silicone substrate that deforms easily, yet containing little islands of a more rigid polymer. The trick is that these little islands are used for mounting the electronic components, or parts thereof. In this way, the lens can be distorted without damaging the electronics.

With the two different materials for the lens, there is another catch the researchers mention in their article. If the refractive indices of the material differs too much, the resulting material may not be transparent enough for the wearer and cause a vague image. Fortunately, the engineers managed to find two materials that barely differ in their refractive index, so their contact lens is perfectly transparent.

Nano fibres

Finally, the electronic components had to be connected. This was not possible using an ordinary electrical wire, as that could have a negative impact on the vision of the user and could even be dangerous. That's why the South Koreans made a network of very long and thin nano fibres, which are all not just conductive, but also very flexible and stretchable (see figure to right). These nano fibres ensure a great connection between the electronic components. And the antenna, which transmits data and which provides the components with wireless power, was also made in the same way.

Finally, the electronic components had to be connected. This was not possible using an ordinary electrical wire, as that could have a negative impact on the vision of the user and could even be dangerous. That's why the South Koreans made a network of very long and thin nano fibres, which are all not just conductive, but also very flexible and stretchable (see figure to right). These nano fibres ensure a great connection between the electronic components. And the antenna, which transmits data and which provides the components with wireless power, was also made in the same way.

Rabbit

The contact lens has already been tested in practice. Based on a trial with a rabbit that wore the lens for a while, the material stays sound and the animal did not indicate any visible irritation from the contact lens. The small display on the lens – actually just a single pixel – clearly indicated when the rabbit's blood-sugar level went too high.

Finally, the materials were subject to a robust endurance test: the researchers slightly stretched and then released the contact lens five thousand times. After this test, the device still functioned perfectly. So it seems that a smart contact lens that can measure crucial bodily functions has clearly come a step closer with this study.

Opening photo www.allaboutvision.com. Other image material: Park et al., Science Advances, 2018.

If you found this article interesting, subscribe for free to our weekly newsletter!