Sustainable chemical sector is viable

According to the Roadmap 2050, published on 7 March, the Dutch chemical sector will be able to comply with the 90% CO2 emission target reduction by 2050. This will, however, require a 63 billion euro investment and far-reaching technological development.

The Roadmap for the Dutch Chemical Industry towards 2050 was conducted by environmental consultancy firm Ecofys and management consultancy firm Berenschot on behalf of the VNCI, the Association for the Dutch Chemical Industry. The main conclusion: considerable CO2 reduction is indeed possible, without detriment to the economic future of the sector. This reduction can be achieved using bio-based raw materials, electrification through renewable energy, closure of the carbon cycle through the re-use of plastics, for example, and through storage of CO2.

There is, however, one catch to this hopeful conclusion. All these investments and measures required to reduce CO2 emissions are only viable for internationally operating companies in the event of a considerable CO2 price, globally. Aware that no such price is likely for now, the sector is appealing to the government to accept responsibility for the unaffordable costs.

The Roadmap mentions various routes which can be taken to achieve the CO2 reduction:

► Bio-based raw materials

At the moment, the chemical sector is strongly focused on the use of fossil fuels as a raw material, and on crude oil in particular. Replacing them with bio-based materials, which can vary from specially grown crops (sugar beet, for example) to garden waste not otherwise usable, can largely close the carbon cycle. The use of biomass is basically CO2-neutral: CO2 is absorbed during its growth in nature, and is released again upon use of the product.

Bio-based materials are actually already partially used, and this is the least expensive and quickest option according to the Roadmap.

► Plastics recycling

This route is particularly promising for plastics: used PET bottles can be recycled into new ones, without any extra raw materials being required. That essentially applies to all used plastics. However, the Roadmap does distinguish between mechanical and chemical recycling. Plastics are sorted and ground down in the former method, which the Roadmap describes as being quick to apply and one of the least expensive options. Further research is required into chemical recycling on the other hand, whereby the plastics are broken down into their original components.

► Electrification

Many chemical processes require heat, which is now mainly supplied using natural gas. However, heat can also be produced using electricity, by incinerating biomass or using eco-friendly hydrogen generated via sustainable electricity. While the technology is more or less available, it is a great deal more expensive than the use of natural gas.

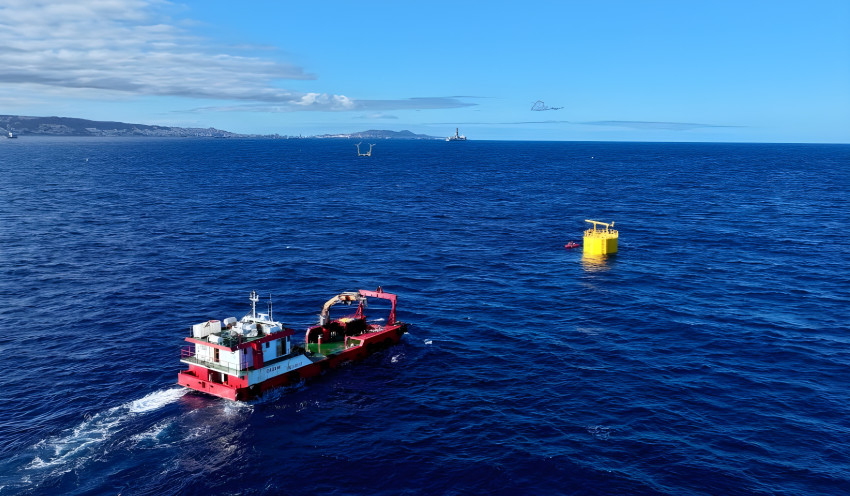

► Storage of CO2

According to the Roadmap, there is sufficient room for the chemical industry to store CO2 in empty oil and gas fields in the North Sea for the next 85 years. The Roadmap defines such storage mainly as an interim measure, only to be applied as long as fossil fuels are still in use. CO2 storage is another of the less expensive measures.

Other sectors

Many of the proposed measures will have consequences not only for the chemical sector, but also for other sectors: logistics chains are necessary for the supply of biomass and the recycling of plastics; there must be an adequate volume of sustainable electricity available; the large-scale use of eco-friendly hydrogen and the storage of CO2 require new infrastructure; and so on. Coordination of all these factors requires an active role by the government, say Ecofys and Berenschot.

Tens of billions

In the most ambitious scenario, both firms quote costs of 63 billion euro, of which 26 billion directly in the chemical sector, 37 billion for the energy system required by the sector, and a further 3 billion annually for the extra fuel and raw materials costs.

This is an enormous operation. It not only ensures that the Netherlands will comply with the climate targets agreed in Paris, but it also creates new economic opportunities. It might even put the Netherlands – given the country’s favourable location on the North Sea – in a leading position in terms of sustainability of the chemical sector, according to the Roadmap.

Opening photo: Chemical plant Pernis in Rotterdam. Photo Danny Cornelissen.

If you found this article interesting, subscribe for free to our weekly newsletter!