Waste-to-energy plant in Duiven to store CO2

The AVR waste-to-energy plant in Duiven is set to capture CO2 and supply it to the local horticulture sector. This relates to a sixth of the plant's total emissions.

AVR is the first waste incineration plant in the Netherlands that is planning to capture CO2 on a large scale. Currently, all greenhouse gas it produces – some 400 kton a year – is discharged up the chimney into the air. The aim is to capture a sixth of this (~60 kton) and supply it in liquid form to the tankers of the Air Liquide gas concern, which will then deliver the CO2 to local greenhouses.

Horticulturists need the CO2 to promote the growth of their plants. Not that the plants absorb all that extra CO2, as they mainly thrive due to the higher CO2 concentration in the air. A significant portion of the captured CO2 therefore dissipates into the air anyway. Yet it still represents an environmental benefit, as horticulturists will no longer need to burn natural gas to release the CO2 they require. And it's there specifically that the CO2 emissions reduction is found.

Existing process

To capture CO2, AVR uses a known process: the flue gas containing the CO2 is conducted through a column containing the substance monoethanolamine. The amine molecules bind the CO2. In the next process step, the CO2 saturated amines are heated so that almost pure CO2 is captured. The process is also applied in other countries for plants that capture CO2.

Energy balance

Capturing CO2 in this way costs a lot of energy, particularly to heat the amines. The existing literature states that some 20-30% of the CO2-releasing energy generated is needed to capture the CO2. That explains the hesitation about getting this type of CO2 project off the ground.

Combination with district heating

This all plays less of a role at AVR, as capture fits well into the existing process there. Project Leader Hans Wassenaar from AVR: ‘We supply steam at 120°C for the heating mains, so we already possess the infrastructure to supply the heat necessary for releasing CO2 from the amines.’ Thus the cost difference between supplying heat and CO2 capture is negligible. And the combination of existing heat demand and the growing season in the greenhouses also synchronises well. ‘In the winter, heat supply takes priority, but in the growing season, when it's less cold outside, we can focus more on CO2 supply.

The volume of CO2 to be captured by AVR in Duiven is geared to expected demand from horticulturists. ‘We've taken that as our starting point.’ According to Wassenaar, the AVR is planning to construct a similar system at its plant in Rozenburg. ‘We can then supply to the CO2 mains that goes to the horticulturists.’

If you found this article interesting, subscribe for free to our weekly newsletter!

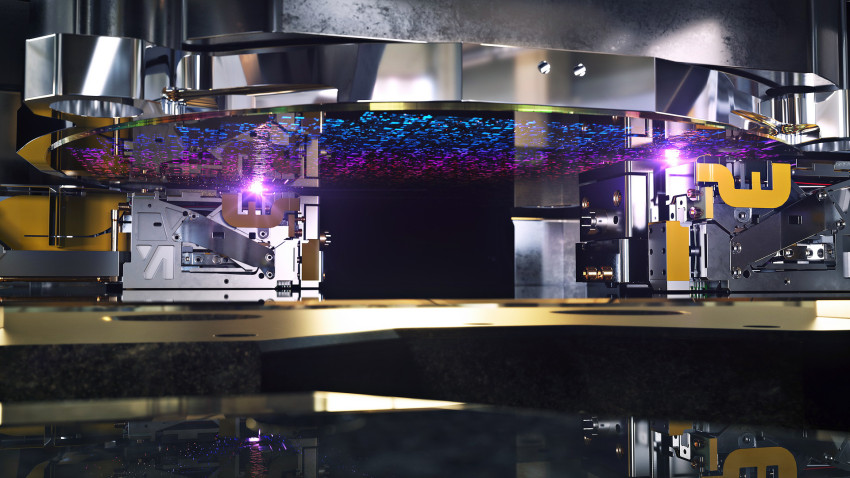

Opening photo: waste incinerator in Duiven.