Asphalt could be made even quieter

The noise of tyres on asphalt is a nuisance for people who live close to a main road. But there's good news: asphalt could be made even quieter by adjusting the size of the pores in the asphalt, the thickness of the layer of asphalt and the smoothness of the surface. This has been demonstrated by the doctoral research of Marieke Bezemer-Krijnen at the University of Twente.

The irritating noise that comes from roads is largely caused by the rush of tyres on the asphalt, with wind noise only becoming dominant at speeds over 100 km/h. Tyres are continually deforming at the point at which they make contact with the road surface, causing the air to vibrate. And that's what causes the noise. This effect is further exaggerated by irregularities in the asphalt.

The noise coming from car tyres is projected to the surroundings, where residents can suffer nuisance. This noise is not only irritating, but it is becoming increasingly obvious that it can cause health problems.

The noise coming from car tyres is projected to the surroundings, where residents can suffer nuisance. This noise is not only irritating, but it is becoming increasingly obvious that it can cause health problems.

Pores make asphalt quieter

The invention of (pervious concrete, ZOAB in Dutch) has already made the asphalt on motorways much quieter. The noise emanating from the tyres is partially absorbed. Thanks to the pores in the road surface, pervious concrete is quieter than old-fashioned sealed asphalt. The precise nature of that process was the subject of doctoral research at the University of Twente.

There, Marieke Bezemer-Krijnen developed a model that predicts the noise-absorption properties of porous asphalt, even before it has been made. And that provides insight into the physical processes that take place. But perhaps even more important: road builders can use this model to prepare the optimal asphalt mix.

Insights

Photo: VBW-Asfalt / CC BY-SA 3.0

Bezemer's work has provided a couple of important insights. Firstly, a high-porosity road (lots of cavities) absorbs sound better. That sounds logical, but it does have a limitation: if porosity is too high, then structural rigidity is compromised. 'In the trial sections of road we laid, we achieved a porosity of 25%, but in practical trials using tyres, the surface actually broke down very quickly,' explains Bezemer-Krijnen.

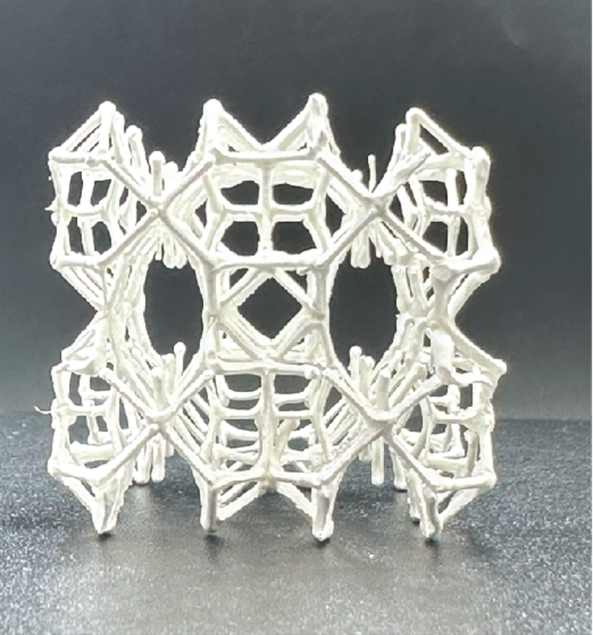

The second insight is that smaller stones – thus smaller pores – in the asphalt lead to better sound absorption. 'Much of the absorption of noise takes place in the boundary layer between air and stone, and with smaller pores, the effect of boundary layers is more dominant.'

Thirdly, Bezemer-Krijnen's study demonstrated that the thicker the layer of porous asphalt, the lower the sound frequencies that are absorbed. The network of pores could therefore run deeper, creating as it were long tubes (with both a closed and an open end), which accommodate longer sound wavelengths.

Finally, a road can be made quieter by making the surface smoother. The small bulges on a road cause the rubber of the tyre to vibrate, and this is a major source of noise. If you could reduce this by reducing the number of bulges, then you tackle the problem at source and don't have to expend so much energy trying to absorb noise.

Scope for quieter asphalt

But what does this all mean for Dutch roads? 'Of course, I don't know about the mix and types of stones used to produce asphalt for all roads. But my impression is that there is still plenty of scope for making asphalt quieter.'

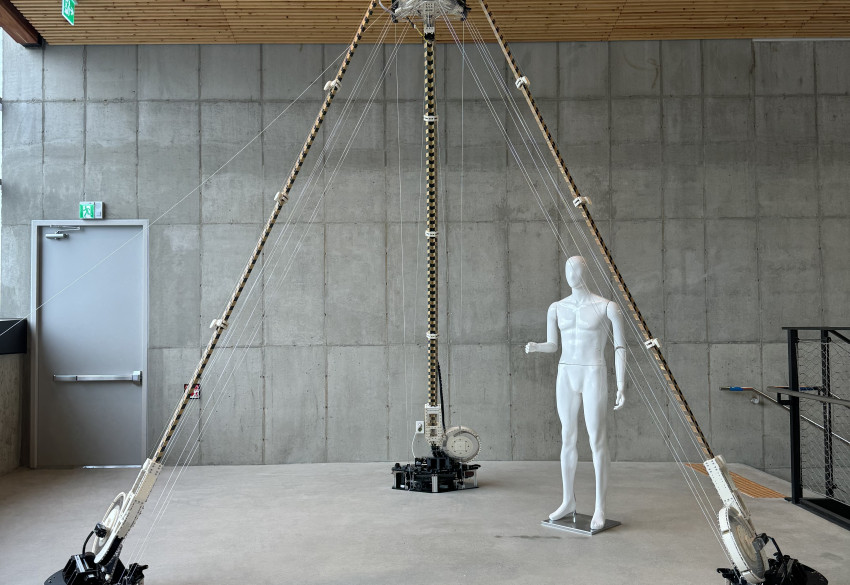

That sounds reasonable, as the PhD student has not only built a model, but also had stretches of road built to carry out measurements to validate the model. At the former Twente airport, road builder Reef Infra laid eight 3m-wide lanes of asphalt, 100m long (see opening photo). Six of these lanes were built using existing combinations of materials and mixes.

Two stretches were built using a new method: the first with a single layer of porous asphalt and the second with two layers of porous asphalt, with one having small stones and the other slightly larger stones. Not only did measurements of these trial roads confirm Bezemer-Krijnen's models, but 'both of the new roads gave better results than existing road types'.

Road builders can now start applying this new knowledge. Bezemer-Krijnen's work was part of the larger project Stil Veilig Wegverkeer [Quiet and Safe Road Traffic]. Under that umbrella, other PhD students carried out research into the impact of the tyre itself on the sound created and into the effect of the road surface on vehicle safety.

Images: Marieke Bezemer-Krijnen