Autonomous boat built by students to take part in US competition

This Friday, the Trident Delft student team will depart for Daytona in the US, where it will be taking part in the RoboBoat competition from 18 to 24 June. This is the first time a Dutch team has taken part in this competition, which puts autonomous boats through their paces with various assignments.

In January, Team Trident students presented their first prototype during the finals of their Robotics minor. They have spent the last few months working hard in their own time to perfect their autonomous boat.

The Trident is a small trimaran measuring 75 by 52 cm, with a weight of 12 kg and a top speed of 1.5 m/s. The students opted for the trimaran design (a hull with two parallel outriggers) because of its stability, essential for the sensors on board to work properly.

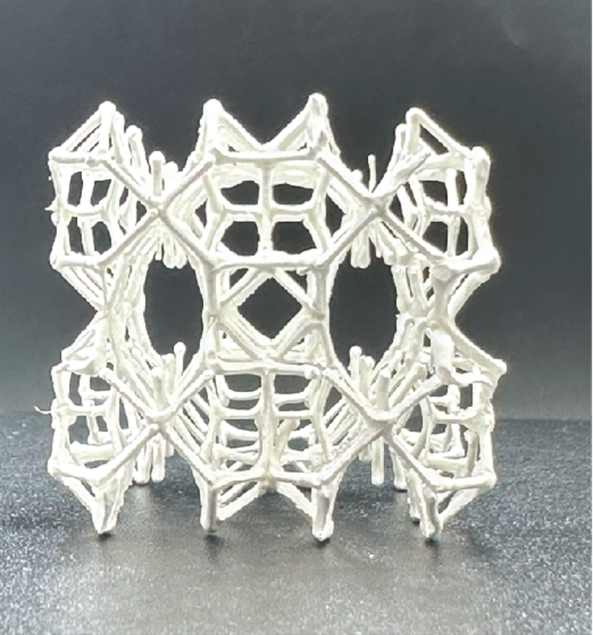

3D printing

The Trident hull is made of fibreglass-reinforced epoxy resin, so it is strong as well as rigid and light. Laser-cut profiles inside the boat provide the necessary stiffness.

The top of the boat is made up of eleven 3D-printed pieces of plastic. 'These contain all the sensors, which place specific demands on positioning and orientation,' says Timothy Puglia, industrial design student at Delft University of Technology and spokesperson for the team. 'The shapes required are therefore quite complicated, so 3D printing was the best option.'

Accurate to the millimeter

Various sensors on the Trident help the boat determine its position. The GPS on board isn’t accurate enough for most assignments, so the Trident also carries an IMU (inertial measurement unit), a box with accelerometers and gyroscopes. The boat uses this equipment to determine its position and that of for instance buoys down to the millimetre.

The Trident also has to 'look' around to identify objects that may pose a problem, or which can be used as navigation aids. Lidar technology is used for this, by far the most expensive part of the boat.

Planning routes

All the data from the sensors is sent to a computer in the boat’s hull. This then controls the various propellers using a differential-thrust approach, where sometimes one screw may be rotating forward and the other reversing so as to steer the boat.

The Trident software can recognise the shapes and colours of objects with a camera, and estimate their distances and locations. In addition, the boat can autonomously plan routes, and search for openings in a row of objects. A drone is needed for one of the assignments, which will take off from the Trident’s deck. 'We’re still working hard on this aspect. We hope to get it sorted out in time,' says Puglia.

Competition

The RoboBoat competition in Daytona, Florida, starts on Monday, 18 June. Student teams from all over the world will be taking part. During a course of up to 20 minutes, competing boats will have to carry out a number of assignments as quickly as possible, such as berthing and unberthing, avoiding obstacles, and sailing through gates.

The team from Delft is taking part in the competition for the first time, while other teams are experienced participants. 'It will be tough,' according to Puglia. 'But we’re very confident about our boat. It sails steadily thanks to the help of Damen Shipyards which worked closely with us.'

Puglia is not yet sure about the tactics of other competitors. 'We shared every inch of our progress on social media, but other teams have been less forthcoming. I’ve seen what lots of boats look like from the outside, but not how they’re controlled.'

Read more details about Team Trident's design in the journal paper (pdf) that the team had to hand in before the competition.

If you found this article interesting, subscribe for free to our weekly newsletter!

Images and video Team Trident