Drone helps inspect planes

At a recent exhibition, aircraft manufacturer Airbus presented a drone designed to inspect damage to planes. In the hangar, the drone flies independently around the aircraft, takes crystal clear photos of the fuselage and sends them to a database for further inspection. Airbus expects the drone to result in faster, better and safer inspection routines.

Passenger planes must be periodically parked in the hangar in order to carefully check them for damage. Bird collisions can cause dents in the fuselage, and hairline cracks can occur as a result of intensive use. Aviation companies are of course very keen to discover such issues at an early stage.

Currently, these types of inspection rounds are relatively time consuming, with engineers studying the plane from ground level, searching for possible problems. An aerial platform is then often used to check the top of the fuselage. And so it can take up to a day to examine an entire plane.

We can speed this up considerably, says Airbus in a press release. Thanks to the new Advanced Inspection Drone, the full inspection can be completed within around three hours.

Faster

A drone has certain advantages of course. It can move past the various monitoring points much faster than a person standing on an aerial platform. Secondly, the drone effortlessly follows the contours of the fuselage, enabling it to take clear photos from the ideal angle. And finally, there are fewer safety risks for the employees in question, as they no longer need to work at heights.

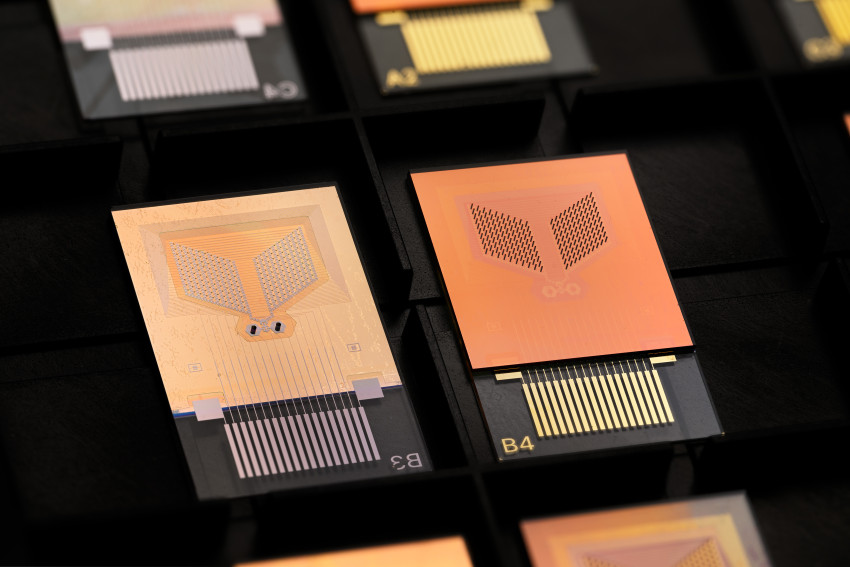

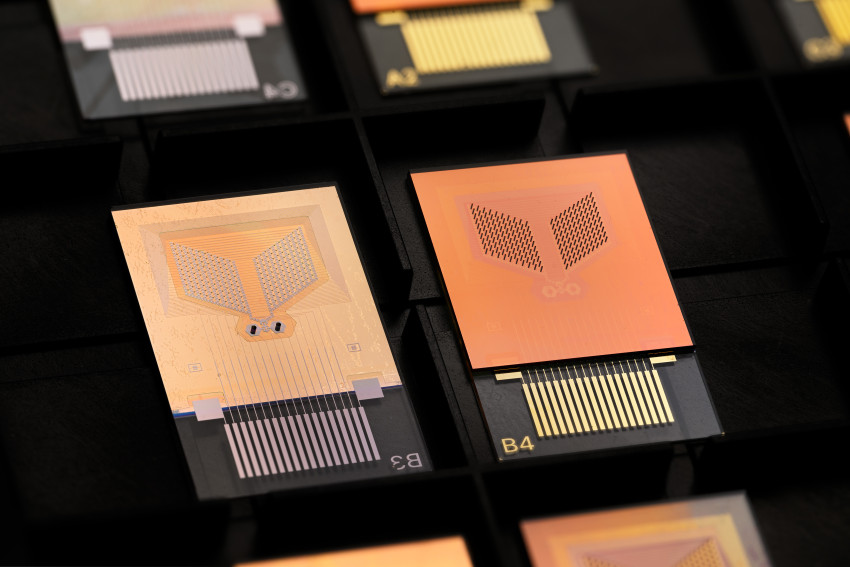

The Airbus quadcopter flies autonomously. Although sent airborne by an operator, it proceeds along a preprogrammed route. A system of lasers on the drone ensures that it always stays at a safe distance from aeroplane components. But to be absolutely certain, there is also a protective shield around the drone's rotors (see photo above).

Marking damage

The images generated by the inspection drone can be followed live on a tablet held by the engineer, who can then mark any striking damage. At the same time, all the images are uploaded to a computer database for subsequent analysis. There, the photos are compared with the digital 3D model of the aircraft, in order to quantify any damage. This process automatically produces a test report.

Airbus hopes to make its new system available to airline companies by the end of this year. However, it still needs to be approved by the European Aviation Safety Agency (EASA), the authority responsible for monitoring aviation safety.

Inspection

Drones have been used to inspect buildings and large installations for some time now, including electricity masts and chimneys. However, most of these drones are operated by a pilot twiddling the knobs. The fact that aircraft inspections take place in a hangar, away from any wind and other weather influences, makes this application more suitable for an autonomous drone.

Birds

Drone technology can also improve other aspects of aviation safety, for example when scaring birds away from airports. On the other hand, there are concerns about clumsy amateurs playing with their toys around airports. There have already been various reports of near collisions between drones and passenger aircraft.

If you found this article interesting, subscribe for free to our weekly newsletter!

Images: Airbus

Meer artikelen

Een AI-fabriek in Groningen

Gezondheid meten via zweetdruppels

Nieuwste artikelen

Een AI-fabriek in Groningen